I-Ductile iron cast ye-track roller end cover

Isingeniso esifushane:

I-Ductile iron, eyaziwa nangokuthi i-ductile cast iron, i-nodular cast iron, i-spherical graphite iron, i-spherical graphite cast iron kanye ne-SG iron, iwuhlobo lwensimbi exutshwe ne-graphite eyatholwa ngo-1943 nguKeith Millis.Nakuba izinhlobo eziningi zensimbi ekhonjiwe zibuthakathaka ekuqineni nasekuqineni, i-iron ductile inomthelela omkhulu kakhulu kanye nokumelana nokukhathala, ngenxa yokufakwa kwayo kwama-nodular graphite.I-Ductile iron ayiyona into eyodwa kodwa iyingxenye yeqoqo lezinto ezingakhiqizwa ngezinhlobonhlobo zezakhiwo ngokulawulwa kwe-microstructure yazo.Isici esivamile esichaza leli qembu lezinto zokwakha ukuma kwegraphite.Kuma-ayina ama-ductile, i-graphite isesimweni samaqhuqhuva esikhundleni sama-flakes njengasensimbi empunga.Nakuba ama-graphite flakes abukhali adala amaphuzu okugxilisa ingqondo ngaphakathi kwe-metal matrix, ama-nodule ayindilinga avimbela ukwakhiwa kwemifantu, ngaleyo ndlela anikeze i-ductility ethuthukisiwe enikeza ingxubevange igama layo.

I-Austempered ductile iron (ADI; okungukuthi, i-austenite tempered[7]) yatholwa ngeminyaka yawo-1950s kodwa yathengiswa futhi yazuza impumelelo eminyakeni ethile kamuva.Ku-ADI, isakhiwo se-metallurgical sisetshenziswa ngenqubo eyinkimbinkimbi yokwelapha ukushisa.

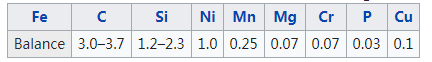

Ukwakheka

Ingxenye enkulu (%) ye-ferritic ductile iron castings[8]

Ezinye izinhlobo ze-iron ductile ngokuvamile zinenani elincane lesulfure.

Ikhabhoni, 3.2–3.60%

I-silicon, 2.2–2.8%

I-Manganese, 0.1–0.2%

I-Magnesium, 0.03–0.04%

I-Phosphorus, 0.005–0.04%

Isibabule, 0.005–0.02%

Ithusi, <0.40%

Insimbi, ibhalansi

Ama-elementi afana nekhopha noma ithini angase angezwe ukuze kwandiswe amandla futhi anikeze amandla ngesikhathi esifanayo kwehliswe i-ductility.Ukumelana nokugqwala okuthuthukisiwe kungafinyelelwa ngokufaka i-15-30% yensimbi ku-alloy ngamanani ahlukahlukene e-nickel, ithusi, noma i-chromium.

I-silicon njengengxenye yokwakheka kwe-graphite ingathathelwa indawo yi-aluminium ukuze inikeze ukuvikeleka okungcono kwe-oxidation.[9]

HONGDAI-Ductile iron castizinto:

Ekuqaleni kuka-2021, i-HONGDA yakha imboni entsha ukwethula izinto zokusebenza kanye nomugqa wokukhiqiza we-Ductile Iron Casting.

1. Okubalulekile: I-QT450#-10 kanye nezinga le-Spheroidization lingaphezu kweleveli III ukuze uthole ikhwalithi enhle yokulingisa ukusekela isicelo sakho.

2. Ulayini wokukhiqiza ozenzakalelayo ukuze ufinyelele ukusebenza kahle okuphezulu kanye nokukhiqizwa kwamandla amakhulu, ama-550T/Inyanga, ukubuyisela isidingo sakho esiphuthumayo.

3.Izicelo: i-ductile iron castings ye-roller collar, abakaki abangenzi lutho nokunye okufana nezingxenye zokulingisa ngaphakathi kuka-70KGS.