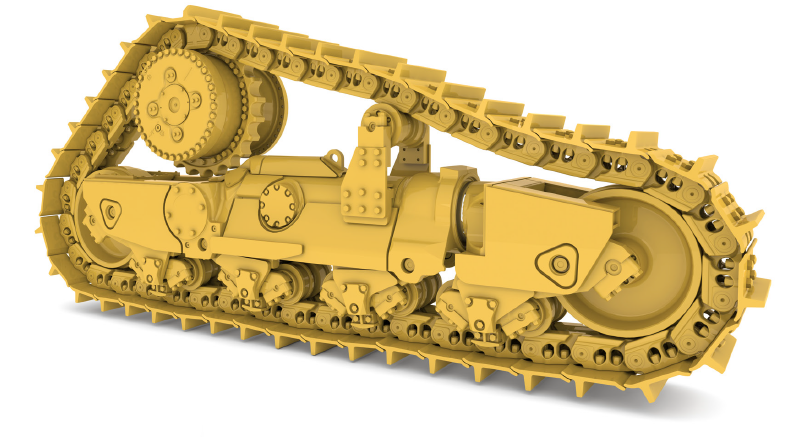

Izindlela zokuxazulula izinkinga zokunakekelwa kwansuku zonke kwe-bulldozer undercarriage

(1) Ithrekhi yesiseshi igcina ukushuba okufanele

Uma i-tension iphezulu kakhulu, i-spring tension ye-idler pulley isebenza ku-track pin kanye ne-track bushing, indilinga yangaphandle yephinikhodi kanye nendilinga yangaphakathi ye-track bushing ibe ngaphansi kwengcindezi ephezulu ye-extrusion, futhi iphini kanye i-track bushing izogqokwa ngaphambi kwesikhathi ngesikhathi sokusebenza.Amandla anwebekayo entwasahlobo nawo asebenza kushafti engenzi lutho kanye nasehlathini, okuholela ekucindezelekeni okukhulu kokuthintana kwendawo, okwenza kube lula ukugaya i-idler bushing ibe yi-semicircle, futhi iphimbo lethrekhi linwebeka kalula, futhi kuzonciphisa ukusebenza kahle kokudlulisela kanye nokumosha ukudluliswa kwenjini ku-sprocket namandla okulandelela.

Uma ukushuba kwethrekhi kuxege kakhulu, ithrekhi izohlukaniswa kalula kumuntu ovilaphayo kanye nerola, futhi ithrekhi izolahlekelwa ukuqondana kwayo okulungile, okuzobangela ukuthi ithrekhi egijimayo iguquguquke, ishaye, futhi ibe nomthelela, okuholela ekugugeni okungavamile kovila. kanye ne-roller.

Ukulungiswa kokushuba kwesiseshi kwenziwa ngokungeza ibhotela embotsheni yokugcwalisa uwoyela yesilinda esicindezelayo noma ukukhulula ibhotela emlonyeni wokulahla uwoyela, nokulungisa ngokubhekisela ekuvunyelweni okujwayelekile kwemodeli ngayinye.Uma ukuphakama kwamasegimenti ethrekhi kunwetshwa kuze kufike lapho kufanele kususwe khona isethi yamasegimenti ethrekhi, indawo exhunywe endaweni yezinyo lesondo lokushayela kanye ne-track bushing nakho kuzogqokwa ngendlela engavamile.Umkhono uyaphendulwa, izikhonkwane eziguge kakhulu kanye nama-track bushings ayashintshwa, bese kushintshwa umhlangano ohlanganyelwe wethrekhi.

(2) Gcina iongenzi luthoindawo iqondanisiwe

Ukungaboni ngaso linye komuntu ongenzi lutho kunomthelela ongathi sína kwezinye izingxenye zendlela yokuhamba, ngakho ukulungisa igebe phakathi kwepuleti le-Idler guide kanye ne-track frame (ukulungisa ukungahambi kahle) kuwukhiye wokwelula impilo yendlela yokuhamba.Lapho ulungisa, sebenzisa i-gasket phakathi kwepuleti likamhlahlandlela ne-bearing ukuze ulungise.Uma igebe likhulu, susa i-gasket;uma igebe lincane, khulisa i-gasket.Imvume ejwayelekile ingu-0.5 kuya ku-1.0mm, futhi imvume ephezulu evunyelwe ngu-3.0mm.

(3) Vula iphinikhodi yethrekhi futhiithrekhi bushingngesikhathi esifanele

Phakathi nenqubo yokuguga yephinikhodi kanye ne-track bushing, i-pitch yethrekhi iyakhula kancane kancane, okuholela ekuhlanganyeleni okubi phakathi kwesondo lokushayela kanye nokuqhuma kwethrekhi, okuholela ekulimaleni kwethrekhi nokuguga okungavamile endaweni yezinyo le-drive. isondo, elizodala ukuzungeza, ukubhakuzisa, kanye nomthelela.Nciphisa kakhulu impilo yendlela yokuhamba.Uma iphimbo lingeke likwazi ukubuya ngokulungisa ukushuba, kuyadingeka ukuthi ujikise iphinikhodi yethrekhi bese ulandela umkhondo ukuze uthole iphimbo elifanele lethrekhi.Kunezindlela ezimbili zokunquma isikhathi lapho iphinikhodi yethrekhi kanye ne-track bushing iphendulwa;enye indlela iwukunquma isikhathi lapho iphimbo lethrekhi inwetshwa ngo-3mm;enye indlela ukucacisa isikhathi lapho ububanzi obungaphandle be-track bushing bugqokwa ngu-3mm.

(4) Qinisa amabhawodi namantongomane ngesikhathi

Uma amabhawodi omshini wokuhamba exega, aphuka kalula noma alahleke, okubangela ukwehluleka uchungechunge.Lawa mabhawodi alandelayo kufanele ahlolwe ukuze anakekeleke nsuku zonke: amabhawodi akhwezayo erola elisekelayo kanye nerola elisekelayo, amabhawudi akhwezayo ebhulokhi yezinyo lesondo lokushayela, amabhawudi akhwelayo e-track shoe, amabhawudi akhwelayo epuleti lonogada, kanye amabhawodi akhuphukayo ekhanda le-brace diagonal.Bheka imanuwali yemiyalo yemodeli ngayinye ukuze uthole itorque eqinisayo yamabhawodi amakhulu.

(5) Ukugcoba ngesikhathi

Ukugcotshwa kwendlela yokuhamba kubaluleke kakhulu.Ama-roller bearing amaningi “ashiswa aze afe” futhi imali ayitholakali ngenxa yokuvuza kukawoyela.Ngokuvamile kunenkolelo yokuthi lezi zindawo ezi-5 ezilandelayo zingavuza uwoyela: ngenxa yendandatho ye-O empofu noma eyonakele phakathi kwendandatho yokugcina kanye ne-shaft, ukuvuza kwamafutha kusukela ohlangothini olungaphandle lwendandatho yokugcina kanye ne-shaft;ngenxa yokungathintani kahle kwendandatho entantayo yophawu noma isici se-O-ring, Amafutha avuza phakathi kwengxenye yangaphandle yeringi namarola (amarola asekelayo, amarola aqondisayo, amasondo okushayela);ngenxa ye-O-ring embi phakathi kwama-roller (ama-roller asekelayo, ama-guide roller, amasondo okushayela) kanye ne-bushing, kusukela ehlathini kanye nokuvuza kwe-Oil phakathi kwama-roller;ukuvuza kwamafutha kupulaki yokugcwalisa ngenxa yepulaki yokugcwalisa okuxekethile noma ukulimala kwembobo yesihlalo evalwe ipulaki ye-conical;ukuvuza kwamafutha phakathi kwekhava kanye ne-roller ngenxa yama-O-rings ampofu.Ngakho-ke, kufanele unake ukuhlola izingxenye ezingenhla ngezikhathi ezijwayelekile, futhi wengeze futhi uzishintshe njalo ngokuhambisana nomjikelezo wokugcoba wengxenye ngayinye.

(6) Hlola ukuqhekeka

Imifantu yesistimu ye-undercarriage kufanele ihlolwe ngesikhathi, futhi ukulungiswa kwe-welding nokuqinisa kufanele kwenziwe ngesikhathi.

Isikhathi sokuthumela: Jun-05-2022