Mku shaft :MI-aterial iyinsimbi yekhwalithi ephezulu ye-carbon structural engu-50Mn, enokuqukethwe kuka-C kusuka ku-0.48 kuya ku-0.56%, okuqukethwe kwe-Si kusuka ku-0.17 kuya ku-0.37%, okuqukethwe kwe-Mn kusuka ku-0.7 kuya ku-1.0%, okuqukethwe kuka-S kusuka ngaphansi kuka-0.035%, okuqukethwe kwe-P kusuka ngaphansi kuka-0.035%, nokuqukethwe kwe-Cr okusukela ngaphansi kuka-0.25 kuya ku-0.30%, okuqukethwe kwe-Ni kusuka ngaphansi kuka-0.30%, nokuqukethwe kwe-Cu okusuka ngaphansi kuka-0.25%. ingathuthukisa i-ductility kanye ne-plasticity yezinto, iqinisekise ukuqina okwanele nokumelana nokugqoka.Ngemuva kokwelashwa kokushisa, insimbi engu-50Mn inamandla aphezulu nobulukhuni, ukungena okuhle kakhulu, ungqimba oluqinile olujulile, nokuthungwa kwepearlite okuhle, nokusebenza okuhle kwemishini.

Izindinganiso zokuklama ze-shaft eyinhloko zidinga ukujula kuka-2 kuya ku-7 mm wengqimba eqinisayo kanye nobulukhuni obushisayo obungu-50 kuya ku-62 HRC.

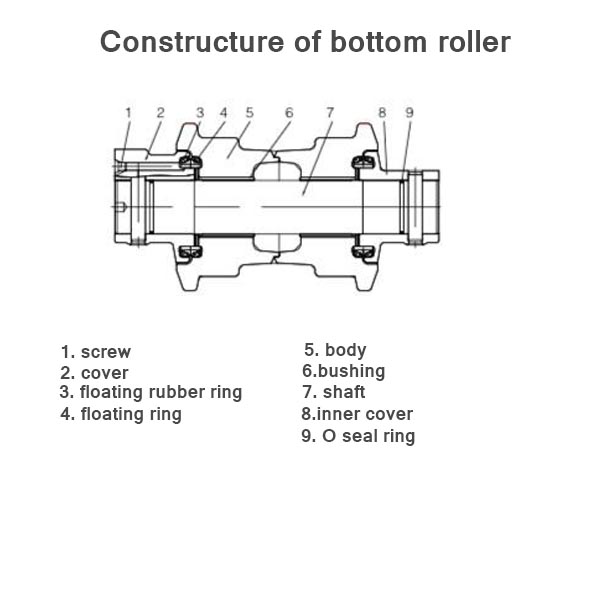

Umzimba :Ukuze uthuthukise ukumelana nokugqoka kweti-rack roller's umzimba, impahla iyinsimbi yesakhiwo esingu-40Mn2 ingxubevange, enokuqukethwe kuka-C kusuka ku-0.37 kuya ku-0.44%, okuqukethwe kwe-Si kusuka ku-0.17 kuya ku-0.37%, okuqukethwe kwe-Mn kusuka ku-1.4 kuya ku-1.8%, okuqukethwe kuka-P kusuka ngaphansi kuka-0.030%, nokuqukethwe kuka-S kusuka ngaphansi kuka-0.030%.

I roller phansiumzimba ubunjwe ngenqubo yokubumba.Ngemva kokubumba, umzimba wesondo omangelengele uyathotshiswa ukuze ufinyelele ubulukhuni be-26-32HRC ukuze kugcinwe amandla aphezulu, ukuqina, ukuqina, nokusebenza komshini kukonke ngaphakathi komzimba wamasondo.Ingaphezulu lomzimba wesondo lingaphansi kokwelashwa okucishayo ukuze kwandiswe ubulukhuni nokumelana nokugqoka kwendawo yesitimela esisekelayo.Ukuqina kokucisha kungu-50-58HRC, nokujula okungu-6-12mm.Lokhu kubangela ukufana okuyisisekelo phakathi kokuqina kobuso besitimela kanye nobulukhuni bokuhlangana kwesixhumanisi seketango (48-58HRC).

Faka uphawu:Ubukhulu nobukhulu obuphezulu be-O-ringkufanele ihambisane nezidingo zokuklama.Indawo yokukhwelana kufanele ibe yindilinga, futhi kufanele kube nokuhlanzwa kwanoma yimaphi ama-burrs namachopho acijile.

Irabha yophawu elintantayo kanye ne-O-indandathokufanele kukhethwe kunjoloba ye-butyl yekhwalithi ephezulu.Ububanzi bangaphakathi, usayizi wentambo, ukunwebeka, ukuqina (Ugu), kanye nokuqedwa kwendawo kufanele konke kuhambisane nezindinganiso.Ngaphambi kokuhlanganiswa, zonke izinto ezingenhla kufanele zihlolwe futhi zifaneleke ngokuhambisana namazinga angenhla ngaphambi kokufakwa.

Igebe :Ukucaciswa phakathi kwe-eksisi eyinhloko ye-eksisi kanye nehabhu elikhonarollerumzimba kufanele ube ngu-0.2-0.4 mm.Uma ujikeleza, akufanele kube khona ukuvimbelainkinganokusebenza okuhle kokuvala, akukho ukuvuza kwamafutha.

Ukuthambisa :Amafutha okuzala kuithrekhi rollr kufanele ijovwe kusetshenziswa ipompo yamafutha.Uma kunesidingo, i-viscosity yamafutha okugcoba ingase yande ngokufanele.Ngaphambi kokujova amafutha okuzala, i-lubricant ephelelwe yisikhathi kufanele ikhishwe.Khona-ke, okokugcoba okusha kufanele kwengezwe emgodini wepulaki yamafutha kuze kube yilapho amafutha ephuma.Uma ujova amafutha okugcoba, isikulufu se-hub cap kufanele sisuswe, futhi ukuphela kwe-oiling kwedivayisi yokugcoba kufanele kucindezelwe ehlombe esiteshini samafutha.I-torque yokuqinisa ipulaki yamafutha kufanele ilawulwe phakathi kuka-157-255 Nm.

Isikhathi sokuthumela: Apr-05-2023